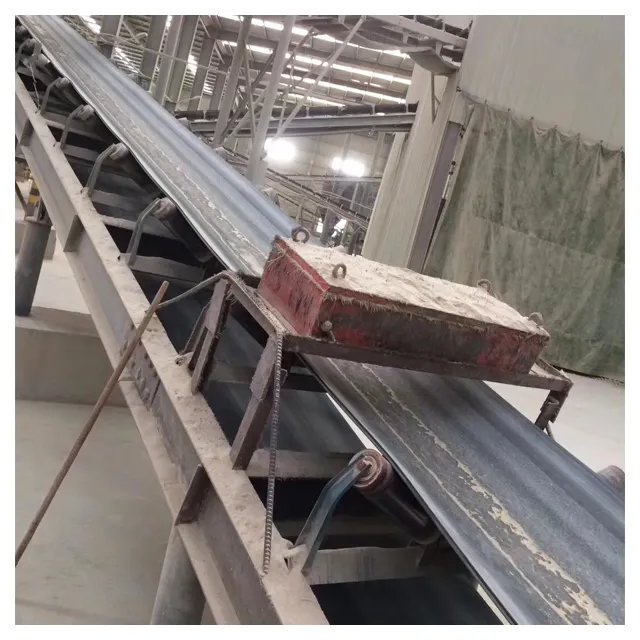

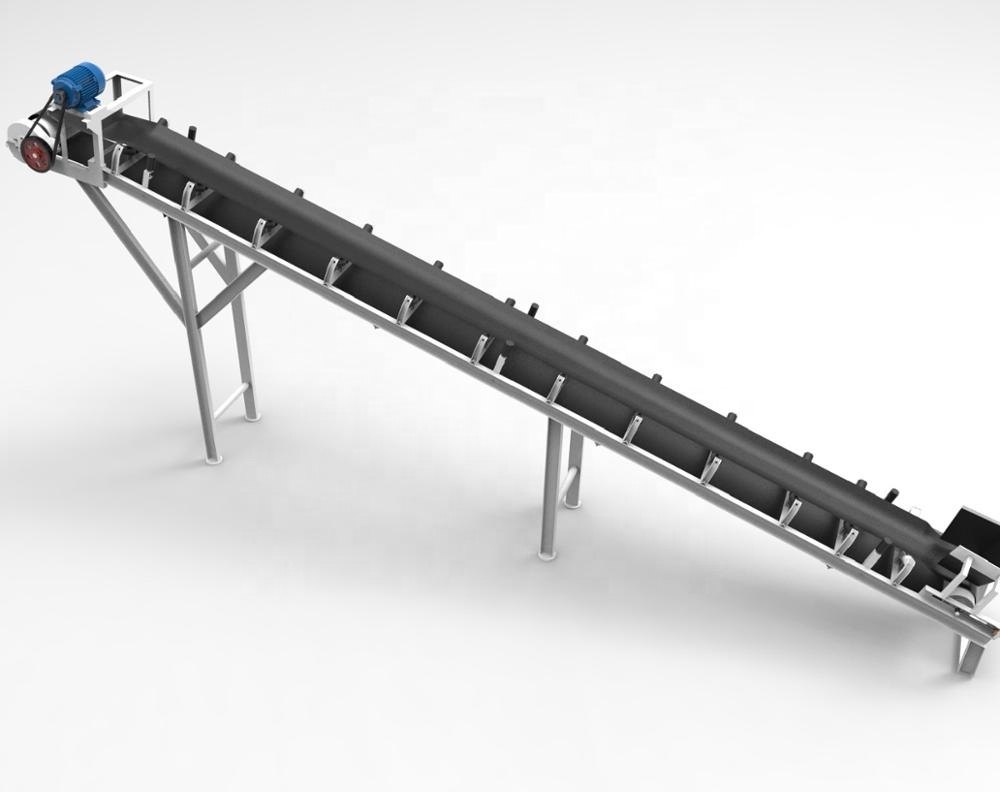

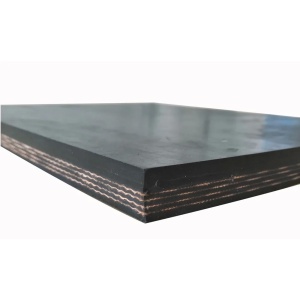

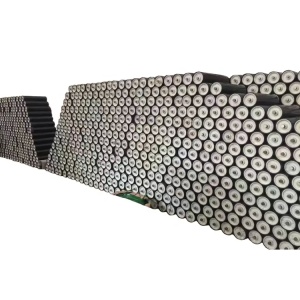

The belt conveyor is one of the best options for bulk materials handling equipment .It can continuously transport materials from one place to another place. Belt conveyor consist of conveyor belt, pulley, idlers, frame, tension devices, driving unit, protection switches and other components etc.

Belt conveyor can convey any type of bulk material – whether powdery, granular, lumpy or bagged – whether cohesive or noncohesive – in almost all industrial fields.

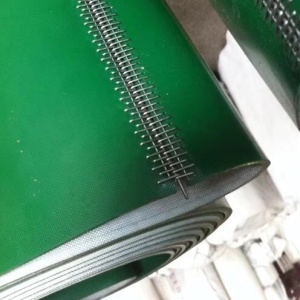

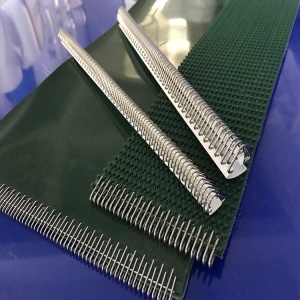

Belt conveyor conveys various materials through the rubber conveyor belt, which riding on heavy-duty troughed idlers, ranging in angles from 20°-45°, each mounted to the steel idler bracket. Belt conveyors can convey material at various inclined angles,typically between 0°-25°.

APPLICATION INDUSTRIES

Mining Industry, Coal Mining Industry, Cement Plant, Coal Handling Plant, Open-pit Mine,

Power Plant, Power Station, Thermal Power Plant, Quarry, Concrete Batching Plant,

Bulk Material Handling Systems, In-plant Conveyor Systems,Grain Handling Systems

|

|

|

| Coal-fired Conveying System In Thermal Power Plant |

Storage Yard Transfer Conveying System In Port | Raw Material Conveying System In Steel Mill |

|

|

|

| Long Distance Conveying System In Open-pit Mine |

Bulk Material Conveying System In Cement Plant |

Sand-Aggregate Conveying System In Crushing Station |

HANDLING MATERIALS

| Aggregates, Frac Sand, Gypsum, Limestone, Clinker, Gravel, Slag, Filter Dusts |

| Coal, Lignite, Copper Ore, Iron Ore, Nickel, lithium Ore, Alumine, Gold Ore, Zinc Ore |

| Animal Feeds, Grain, Salt, Sugar, Biomass Fuel, Municipal Waste, Sewage Sludge, Woodchips |

| Fertilizer, Urea, Inorganic Chemicals,Organic Chemicals, Petroleum Coke, Potash, Pulp & Paper |

FEATURES AND BENEFITS

| Optimum Performance | Increased Safety | |||||||||||

| Optional self-aligning idlers can effectively prevent belt deviation. | Skirts fitted at the feeding point, fully sealed hood at the head section, improve the working environment. | |||||||||||

| Stable operation, no relative movement between the material and the conveyor belt, to prevent materials spillage and damage. | All kinds of protection switches give early warning of possible accidents. | |||||||||||

| Lower Maintenance Cost | Guaranteed Quality | |||||||||||

| Automatic control, reduce maintenance personnel, save labor costs. Interchangeable standardized spare parts to reduce purchase cost. |

Over 30 years of professional manufacturing experience and more than thousands of successful projects for end users at home and abroad. | |||||||||||

| Rapid replacement of spare parts, significantly reducing costly downtime. | Scientific design, advanced processing equipment, experienced technicians and skilled workers, complete quality inspection system to ensure the quality of the products. | |||||||||||

Specifications

| Belt Conveyor Technical Specifications | ||||||||||

| Belt width(mm) | Belt speed (m/s) | |||||||||

| 0.8 | 1.0 | 1.3 | 1.6 | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | 6.5 | |

| Capacity (m³/h) | ||||||||||

| 500 | 69 | 87 | 108 | 139 | 174 | 217 | ||||

| 650 | 127 | 159 | 198 | 254 | 318 | 397 | ||||

| 800 | 198 | 248 | 310 | 397 | 496 | 620 | 781 | |||

| 1000 | 324 | 405 | 507 | 649 | 811 | 1014 | 1278 | 1622 | ||

| 1200 | 593 | 742 | 951 | 1188 | 1486 | 1872 | 2377 | 2971 | ||

| 1400 | 825 | 1032 | 1321 | 1652 | 2065 | 2602 | 3304 | 4130 | ||

| 1600 | 2186 | 2733 | 3444 | 4373 | 5466 | |||||

| 1800 | 2795 | 3494 | 4403 | 5591 | 6989 | 9083 | ||||

| 2000 | 3470 | 4338 | 5466 | 6941 | 8676 | 11277 | ||||

| 2200 | 6843 | 8690 | 10863 | 14120 | ||||||

| 2400 | 8289 | 10526 | 13158 | 17104 | ||||||

| Remark:Capacity is caculated by material horizontal conveyoring ,20°Operating stacking Angle,35°roller groove Angle . | ||||||||||

Selection instructions

1.Material to be conveyed:______

2.Handling capacity: ______ t/h

3.Bulk Density:______ t/m3

4.Center distance between the head and tail pulley:______ m

5.Max. granule size of the feeding material:______ mm

6.Max. Granule’s percentage in whole material:______ %

7.What equipment is used to feed the material into the belt conveyor :______

8.What equipment is used to discharge the material from the belt conveyor :______

9.Working power supply: ______ V ______ HZ

10.Does the belt conveyor work alone or with other equipment to form a system? If forming a system, do you have preliminary design or hand-drawn sketch? If have,please send it to our engineer for reference.