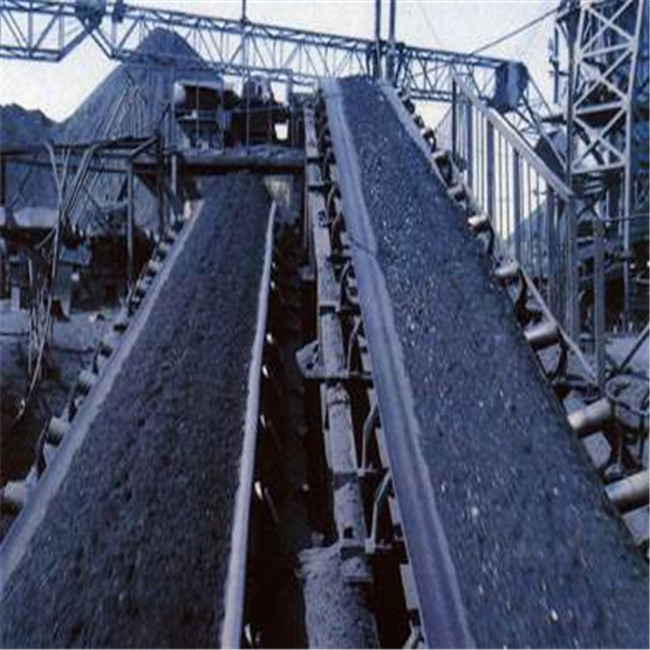

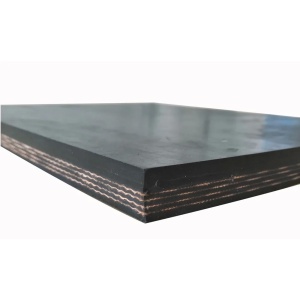

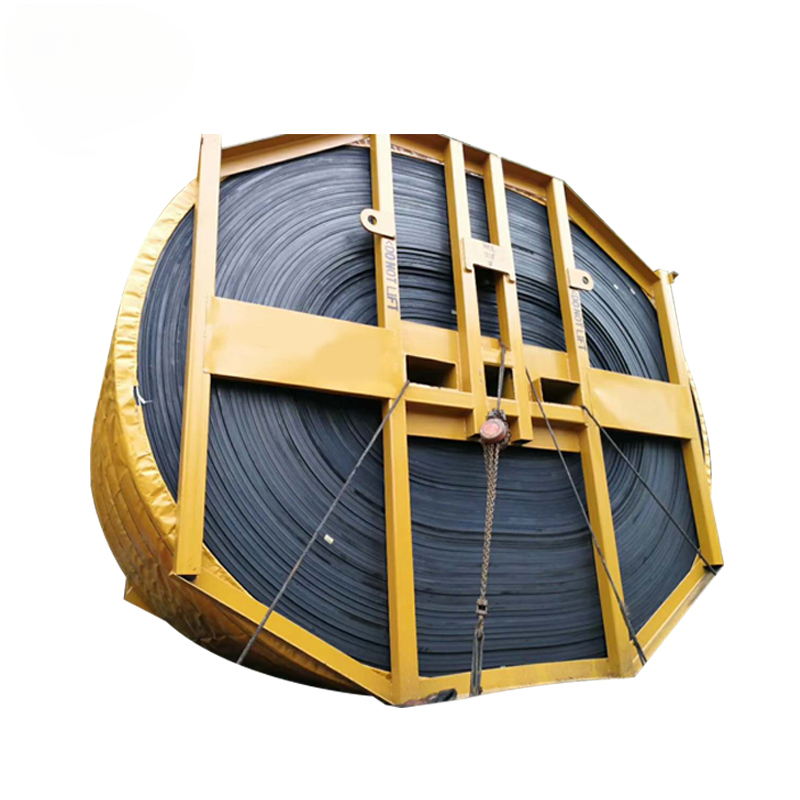

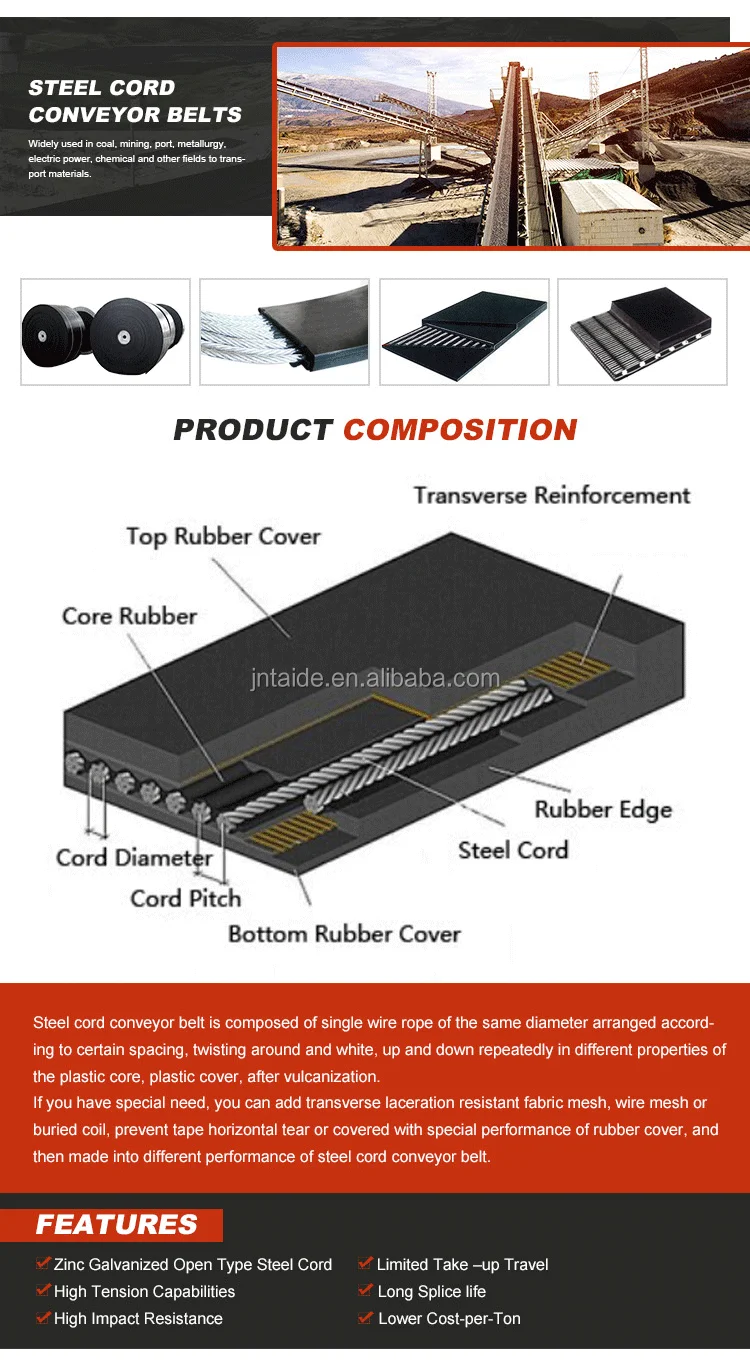

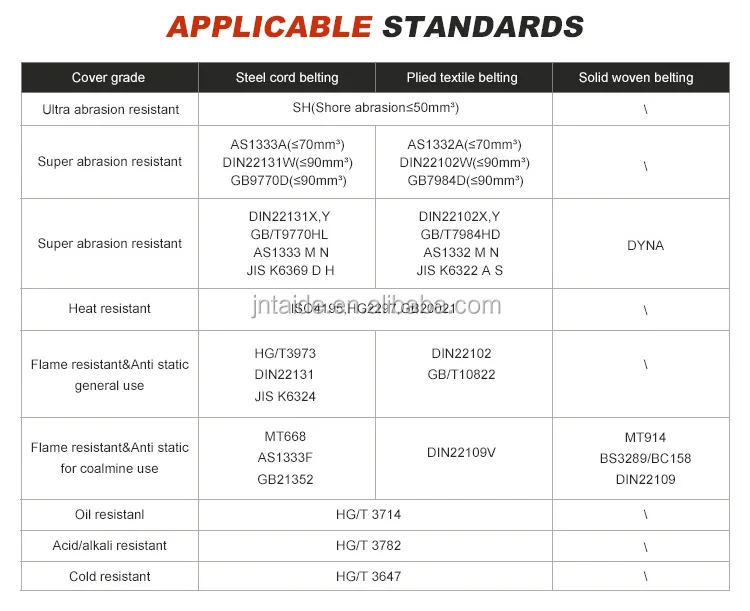

The steel cord conveyor belt (intensity range of 630 ~ 10000 n/mm), plied textile conveyor belt (intensity range of 100 ~ 630 n/mm), Solid woven conveyor belt (intensity range of 680 ~ 4000 n/mm) three big series. Steel cord belt according to the structure is divided into standard structured, tearing resistance, integrated steel net, plied texile conveyor belt according to the skeleton materials are divided into: EP polyester canvas, nylon canvas NN, CC, cotton canvas, solid woven conveyor belt was divided into PVC, PVG type etc. Cover types including wear resistance, heat resistance, flame retardant, resistance to oil, acid and alkali resistant, cold resistant type, etc.

Steel cord conveyor belt is composed of single wire rope of the same diameter arranged according to certain spacing, twisting around and white, up and down repeatedly in different properties of the plastic core, plastic cover, after vulcanization. If you have special need, you can add transverse laceration resistant fabric mesh, wire mesh or buried coil, prevent tape horizontal tear or covered with special performance of rubber cover, and then made into different performance of steel cord conveyor belt.

|

Serial Number

|

Features & Benefits

|

|

1)

|

Zinc Galvanized Open Type Steel Cord

|

|

2)

|

High Tension Capabilities

|

|

3)

|

Limited Take –up Travel

|

|

4)

|

Long Splice life

|

|

5)

|

High Impact Resistance

|

|

6)

|

Lower Cost-per-Ton

|

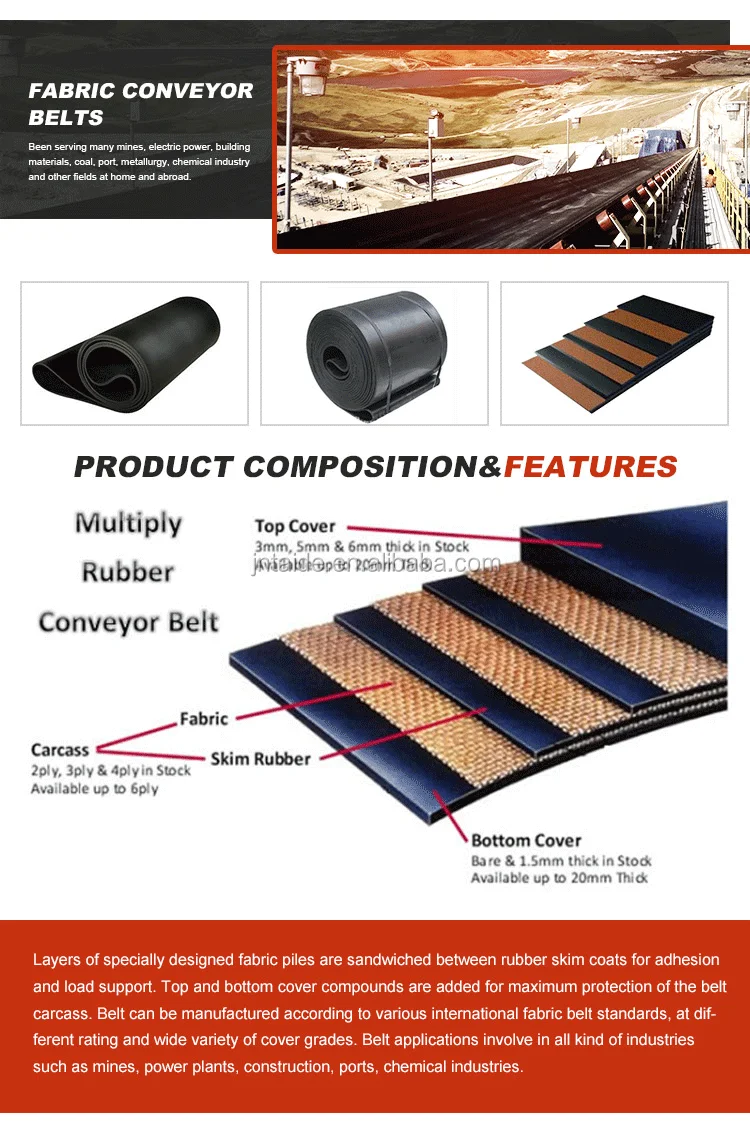

Skeleton force body for canvas, covering up and down in a variety of different cover rubber after vulcanization.

EP Belt’s Feature & Benefits

- 1) Small elongation

- 2) High modulus, high cost performance

- 3) Cover types and the thickness can have a variety of choices

NN Belt’s Feature & Benefits

- 1) High Tension strength

- 2) High strength corrugated canvas effectively absorb the impact

- 3) Cover types and the thickness can have a variety of choices

CC56 Belt’s Feature & Benefits

- 1) Small elongation

- 2) Cover types and the thickness can have a variety of choices

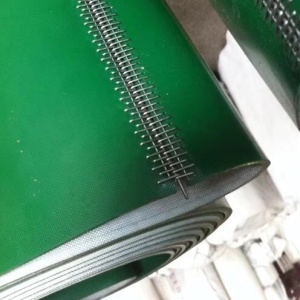

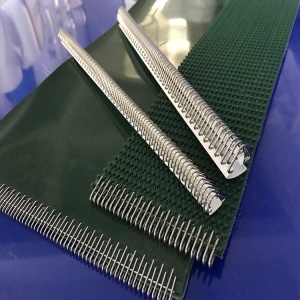

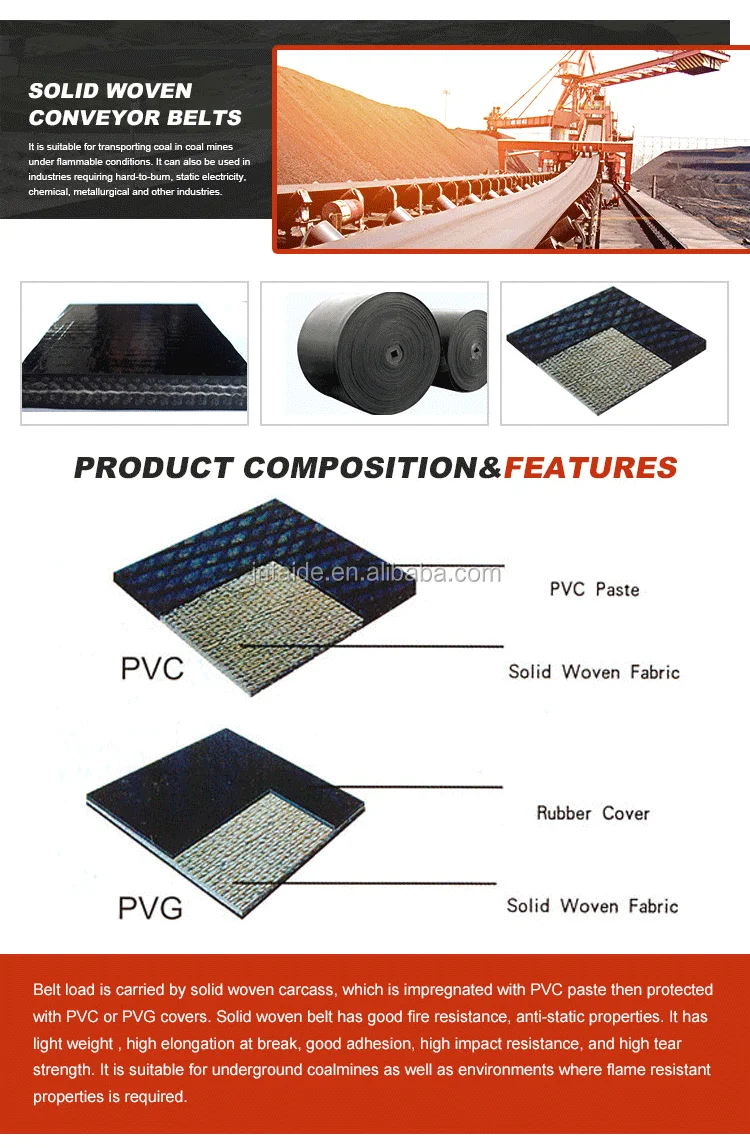

PVC tape is made from cotton and polyester or nylon fiber and twisted into a thread, according to different core structure and intensity, respectively into three or four layers and five layers of cored by dipping, plasticizing come together.

Whole core flame retardant conveyor belt, rubber belt core classics by whole a dipping, plasticizing, coating transition layer, and then the rolling joint upper and lower cover glue, then through curing and cooling. Up and down the product cover are nitrile rubber, can be used in Angle in below 20 ℃ water wet, dry environment can get better application.

PVC Belt’s Feature & Benefits

- 1) Advanced impregnation technology

- 2) Excellent bending performance

- 3) High coupling efficiency

- 4) Excellent safety performance

PVG Belt’s Feature & Benefits

- 1) High tenacity skeleton material

- 2) Advanced impregnation technology

- 3) Performance of the rubber cover

- 4) Excellent flame retardant performance

|

Belt Tension Rating (China Standard)

|

Tensile Strength (Min.)

|

Reference Carcass Gauge(mm)

|

Reference Carcass Weight(KG/㎡)

|

Cover Grade And Recommended Gauge (mm)

|

Reference Belt Width (mm)

|

||||

|

Warp(N/mm)

|

Weft(N/mm)

|

PVC Pressed

|

PVG

|

||||||

|

680S

|

680

|

265

|

6.5

|

8.5

|

1.5+1.5

|

1.5+1.5

|

500-2200

|

||

|

800S

|

800

|

280

|

7.0

|

9.0

|

1.5+1.5

|

1.5+1.5

|

|||

|

1000S

|

1000

|

300

|

8.0

|

10.5

|

1.5+1.5

|

1.5+1.5

|

|||

|

1250S

|

1250

|

350

|

9.5

|

12.5

|

2.0+2.0

|

2.0+1.5

|

|||

|

1400S

|

1400

|

350

|

10.0

|

13.0

|

2.0+2.0

|

2.5+1.5

|

|||

|

1600S

|

1600

|

400

|

10.5

|

14.0

|

2.0+2.0

|

2.5+1.5

|

|||

|

1800S

|

1800

|

400

|

11.5

|

15.0

|

2.0+2.0

|

3.0+2.0

|

|||

|

2000S

|

2000

|

400

|

12.5

|

16.5

|

2.0+2.0

|

3.0+2.0

|

|||

|

2240S

|

2240

|

450

|

14.0

|

18.5

|

3.0+2.0

|

3.0+2.0

|

|||

|

2500S

|

2500

|

450

|

15.0

|

20.0

|

3.0+2.0

|

3.0+3.0

|

|||

|

2800S

|

2800

|

450

|

16.5

|

22.0

|

3.0+3.0

|

5.0+3.0

|

|||

|

3100S

|

3100

|

450

|

18.0

|

24.0

|

Selection based on conveyor systems

|

||||

|

3400S

|

3400

|

450

|

20.0

|

26.0

|

|||||

|

Cover Grade

|

Working Temperature Range

|

Peak Temperature In Short Period

|

|

T1

|

-20℃-+100℃

|

140℃

|

|

T2

|

-20℃-+125℃

|

175℃

|

|

T3

|

-20℃-+150℃

|

220℃

|

|

T4

|

-20℃-+175℃

|

300℃

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* We provide 24hours/7days after-sale service.

* Regularly visit our clients and keep quality tracking.